Benefit from our experience. We can help you

achieve a higher level of efficiency with a new

design/redesign of workflow and workshop

according to lean principles.

Benefit from our experience. We can help you achieve a higher level of efficiency with a new design/redesign of workflow and workshop according to lean principles.

Short and simple handling distances

—

Easy production overview

—

No working against workflow direction

—

Implementation of NEW Technology

—

Maximum efficiency with reduced workload

—

Ergonomically and environmental friendly

KUNZ Turnkey

scope of services

IDENTIFY

with the client

> Existing issues

> Final goals

> Target throughput

> Future scope of works

REVIEW

> Existing layout

> Space requirements

> Existing machinery

> Required machinery

> Actual procedures and cycle times

DEVELOP & DESIGN

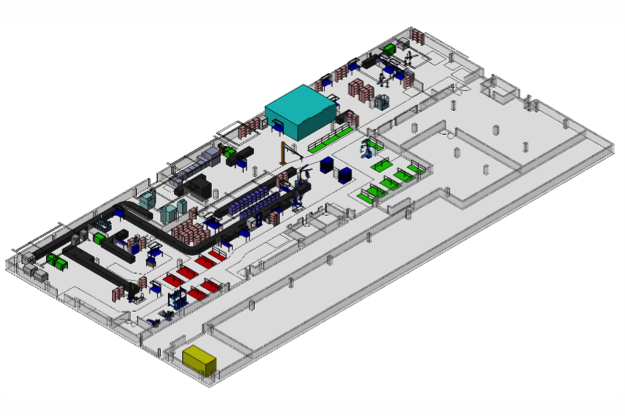

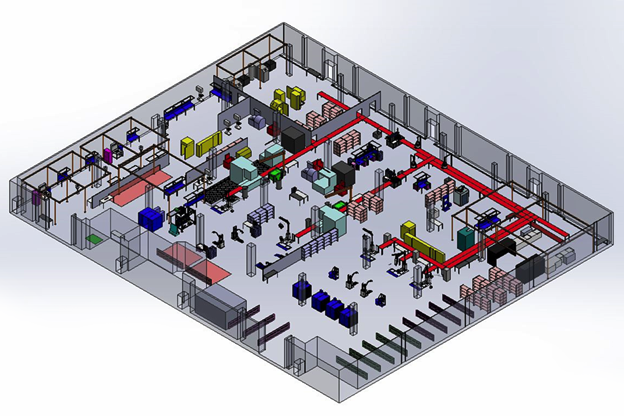

DEVELOP

& DESIGN

in order to DEFINE SPACES

for best suiting WORKFLOWS

> Provide, upgrade or relocate equipment

> Calculate required work force

> Ascertain throughput

> Arrange “On the Job-Training” to implement workflows

LEAN WORKFLOW DESIGN according to CMM and FAA / EASA compliance standards or company principles.

RESULTS

in the Workshop

> DECREASE COMPLEXITY

> Achieve maximum OVERVIEW & TRANSPARENCY

> Reduce human factor influence by IMPLEMENTING NEW TECHNOLOGY (automation, RFID monitoring)

> Improve EFFICIENCY & CAPACITY

> Avoid wasting resources

> MEASURE SUCCESS

KUNZ services for

Turnkey Solutions

Market analysis based on factors such as cost efficiency and availability of required equipment

—

Selection of the best machines tailored to shop requirements and latest technology

—

Evaluation of the resulting space requirements

—

Delivery and positioning of the machines with design of a shop layout to assure an efficient work flow

Previous

Next